By Aura Mihai, Antonela Curteza, Ramona Budeanu & Dorin Ionesi. Gheorghe Asachi Technical University of Iași (TUIASI)

How emerging is additive manufacturing?

Additive manufacturing, or 3D printing, has rapidly emerged as a transformative technology across various industries, notably in fashion and textiles, where it enables the creation of intricate designs while minimising material waste (Melnikova et al., 2015). In fashion design, 3D printing has revolutionised the creation of complex patterns and shapes that were once impossible with traditional methods (Vaezi et al., 2013). Designers like Julia Koerner and Iris van Herpen have showcased 3D-printed garments, demonstrating the integration of this technology into high fashion (Pei et al., 2015).

One of the key advantages of 3D printing in textiles is its sustainability. Unlike conventional textile manufacturing, which often generates significant waste, additive manufacturing uses only the materials needed, reducing environmental impact. Furthermore, the development of biodegradable and recycled materials for 3D printing further supports eco-friendly practices in the industry (Garg et al., 2023).

3D printing also plays a crucial role in preserving cultural heritage. By employing digital models and 3D printing, artists and researchers can recreate intricate cultural patterns, preserving traditional designs while adapting them to contemporary textile needs. This merging of traditional craftsmanship with modern manufacturing techniques creates new possibilities for the preservation and innovation of cultural heritage (Neumüller, M et al., 2014; MIT, 2025; Brination, 2025).

However, challenges persist, especially in large-scale production, cost efficiency, and material performance (Khajavi, 2021). While advancements in multi-material printing and adhesion techniques have made 3D-printed textiles more feasible, further research is needed to fully integrate these technologies into mass production (Grimmelsmann et al., 2018). Nonetheless, the continued evolution of 3D printing in textiles underscores its emerging significance in the industry.

Case study: A Fusion of Tradition, Technology, and Sustainable Fashion

On March 10, 2025, at UNESCO Headquarters in Paris, as part of the international project The Living Thread, products created using additive technologies (3D printing) by Theona Chelariu, Alina Iacob, Raluca Lupu, Iuliana Streba, and Radu Firicel—master’s and doctoral students from the Faculty of Industrial Design and Business Management (TUIASI)—were displayed.

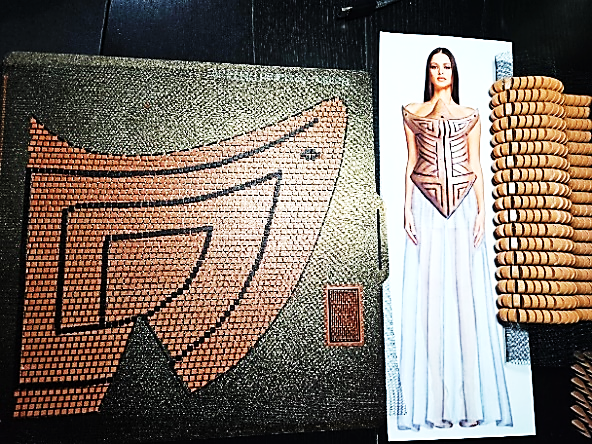

By using 3D printing, the students explored new forms of artistic expression, transforming prehistoric symbols of an ancient civilisation (Cucuteni- https://en.wikipedia.org/wiki/Cucuteni%E2%80%93Trypillia_culture ) into contemporary aesthetics. Titled «Echoes of the Cucuteni Civilization,» the capsule collection proposed a dialogue between cultural heritage and digital innovation, reinterpreting elements of the Cucuteni civilisation through emerging technologies. This fusion of tradition and technology highlights the potential of digital techniques in sustainable and experimental design.

The 3D-printed products were incorporated into conceptual fashion pieces, reflecting the blend of traditional craftsmanship and advanced production methods. This intersection between fashion design and 3D printing opens up new perspectives on the creative process, offering a concrete example of how innovation can transform artistic expression and functionality in fashion.

Access to advanced educational resources and cutting-edge technologies enabled the students to experiment and integrate additive technologies into their creative process. The exhibition of these works at UNESCO Headquarters in Paris marks a significant milestone in the academic and professional journey of the students, providing them with international visibility and opportunities for collaboration. This initiative is part of a broader effort, integrated into the Romanian Creative Week 2025 program (www.rcw.ro), Romania’s largest event dedicated to the creative industries.

Source: Preparation of CRAFTIT 4SD capsule collection at TUIASI

At the heart of the collection lies the harmonious blend of traditional craftsmanship and 3D printing technology. Some pieces incorporate 3D-printed panels and accessories, while others feature embossed elements created with 3D-printed molds, giving garments an added layer of texture and depth. These futuristic techniques imbue the designs with a powerful, almost armor-like quality—symbolising the strength and resilience of the Cucuteni people. The use of additive manufacturing not only brings their intricate patterns to life but also pushes the boundaries of sustainable fashion, offering an innovative approach that reduces waste and enhances creativity. The color palette draws inspiration from the earth tones that defined the Cucuteni way of life—rich terracotta, deep ochre, charcoal black, and soft white. These hues, reminiscent of the pigments found in their pottery, are reinterpreted in modern textiles that carry the spirit of the past while embracing sleek, contemporary silhouettes.

Source: Romanian Creative Week

Echoes of the Cucuteni Civilization transcends the boundaries of a traditional fashion collection. It demonstrates that fashion is not merely about clothing—it’s about storytelling, culture, and the evolution of human creativity, all while embracing the principles of sustainability. Through 3D printing and additive manufacturing, this collection proves how technology can transform fashion, making it more sustainable, expressive, and connected to our cultural roots.

References

Garg, M., Rani, R., Meena, V.K., Singh, S., (2023). Significance of 3D printing for a sustainable environment. Materials Today Sustainability, 23, 100419.

Grimmelsmann, N., Kreuziger, M., Korger, M., Meissner, H., Ehrmann, A., (2018) Adhesion of 3D printed material on textile substrates. Rapid Prototyp. J., 24, 166–170

Khajavi, S., (2021). Additive Manufacturing in the Clothing Industry: Towards Sustainable New Business Models. Appl. Sci., 11(19), 8994

Melnikova, R., Ehrmann, A., Finsterbusch, K., (2014). 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials, Proceedings of the Global Conference on Polymer and Composite Materials, China

Neumüller, M., Reichinger, A., Rist, F., Kern, C. (2014). 3D Printing for Cultural Heritage: Preservation, Accessibility, Research and Education, In: Ioannides, M., Quak, E. (eds) 3D Research Challenges in Cultural Heritage

Pei, E., Shen, J., Watling, J. (2015) Direct 3D Printing of Polymers onto Textiles: Experimental Studies and Applications. Rapid Prototyping Journal, 21(5), 56 – 571.

Vaezi, M., Seitz, H., Yang, S. (2013). A Review on 3D Micro-Additive Manufacturing Technologies. International Journal of Advanced Manufacturing Technology, 67(5-8), 1721-1754.

*** Redefining Design: Textiles at the Intersection of Tradition and Technology, https://design.mit.edu/news/redefining-design-textiles-at-the-intersection-of-tradition-and-technology (accessed on February, 04, 2025)

*** Modern 3D Printed Reflections on Traditions & Cultural Heritage: Foraeva x Stratasys @ Milan Design Week, https://www.irenebrination.com/ (accessed on February, 04, 2025)